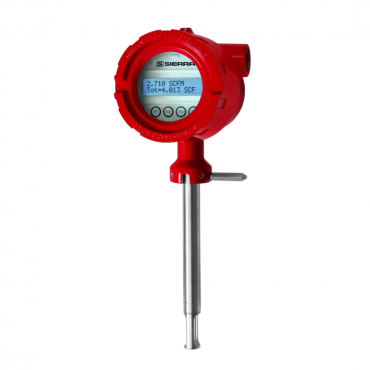

Sierra BioTrak™ 645i/745i Wastewater Dedicated Thermal Mass Flow Meter

- Brand: image/catalog/sierra.jpg

- Product Code: 645i 745i

All the Meter You Need

Sierra’s BioTrak meets the rugged demands of municipal and industrial wastewater plants where aeration, digestion, and cogeneration play pivotal roles. The BioTrak is designed and manufactured to be the best-performing flow meter in the wastewater industry. It makes operators smarter and their processes more reliably efficient. BioTrak is created specifically for plant engineers focused on renewable wastewater processes where healthy microbial growth is crucial. It provides the precise measurements and control required to optimize aerobic and anaerobic treatment and produce biogas.

Simple. Fast. Effective.

With AC or DC power input, optional hot tap capability, and remote configuration, BioTrak is easy to install, operate and adjust in the field to avoid costly and time-consuming delays. Have a look at its digital platform: DigiSense, BioSelect, and BioView. They gather, preview, and deliver the data that supports your processes and meets regulations. Sierra BioTrak’s proven technology makes trust possible. And with reduced maintenance over the lifetime of the instrument, BioTrak significantly lowers cost. Fast and Flexible, BioTrak offers the flexibility to monitor multiple gas types at the push of a button, rotate the housing as needed for tight installations, and configure meter settings from advanced software. Both AC and DC power inputs are available.

BioTrak 645i Insertion / 745i Inline

The BioTrak is available in insertion (645i) and inline (745i) models and in a remote version with junction box and cable. A USB port to connect to a computer or laptop is standard for insertion and inline configurations; interface options include HART or Modbus RTU (RS485).

Features:

- Field-Selectable Gases-air, methane, digester gas

- Direct mass flow measurement maintains precise control of aeration, digestion, and cogeneration

- Air: +/-1% of reading +/-0.2% of full scale - Other gases: +/-1.5% of reading +/-0.5% full scale

- Insertion and inline versions

- AC or DC power input available

- Optional hot top packing gland and retractor

- Integral and remote electronic configurations available

- Wide measurement range up to 1000:1 turndown; 100:1 typical

- BioCal Calibration Validation within five minutes

Digital Platform

How BioTrak Works

The BioTrak measures gas flow rate in standard units without the need for temperature or pressure compensation. It provides two galvanically isolated 4-20mA analog outputs, HART communication (optional), a pulse output, switch input, and Modbus RTU (RS485) (optional).

Sierra’s BioTrak flow meters use a constant temperature differential (constant ΔT) technology to measure the mass flow rate of gases. The thermal mass flow sensor consists of two Resistance Temperature Detectors (RTD’s). The Reference RTD measures the gas temperature. Meanwhile, the instrument electronics heat the mass flow sensor, or heated element, to a constant temperature and measures the cooling effect of the gas flow. The electrical power required to maintain a constant temperature differential is directly proportional to the mass flow rate of the gas.

DigiSense™ Sensor

DigiSense is the state-of-the-art sensor technology used in BioTrak. The thermal sensor interfaces directly with the BioTrak microprocessor for greater control, precision, and programmability. DigiSense accurately responds to changes in process variables (gas flow rate, pressure, and temperature) to determine mass flow rate, totalized flow, and temperature.

DigiSense’s correlation algorithms allow the meter to be calibrated on a single gas in the factory while enabling the user to select other gases in the BioSelect menu.

BioSelect™

To meet the monitoring needs of Process Engineers, BioSelect allows users rapid gas selection or digester gas mixing from a pre-calibrated list of gases, including air, methane, and digester gas mix in the field. With an optional on-board 2-line x 16-character backlit display, operators can view flow rate, total, elapsed time, process gas temperature, and alarms. The display is also used with the configuration panel to access flow meter settings, such as 4-20mA and pulse output scaling, pipe diameter, low flow cutoff, flow filtering (damping), display options, and high or low alarm limits.

BioView™

Sierra’s BioView advanced software is a free PC-compatible application available for download from Sierra’s website. Connect your Windows-based laptop or PC to the meter using the USB port interface to access meter data and configure the meter’s settings.

BioView Features

- Quick access to all configuration parameters with pop-up windows and pull-down menus

- Selection of measurement units, flow and temperature ranges, alarm settings and more

- Print or save a BioCal Calibration Validation Certificate

- Set alarms; display alarm codes

- Simulation mode used to align 4-20mA output with the input to the customer's PLC/DCS

- Raw data to be viewed to diagnose or troubleshoot your meter

- Data logging to an Excel® spreadsheet

BioCal™ Calibration Validation

For customers needing a quick and easy way to verify the meter's calibration in the field, BioTrak offers BioCal™. Initiate this feature through the meter's optional display configuration panel or the BioView software. The test takes less than five minutes to run and produces a pass/fail result afterwards.

Using the BioCal test with BioView software, you can produce a Calibration Validation Certificate upon conclusion. The certificate will show the date and time of the test along with meter data such as firmware version and meter serial number. This in-situ calibration validation helps operators comply with environmental mandates and eliminates the cost and inconvenience of annual factory calibration.

Product Benefits

Dedicated Accuracy

- BioSelect™ menu provides field selectable air, methane, and digester gas

- Designed to deliver accurate flow measurement for aeration, digester, and cogeneration applications

- Air: ±1% of reading ±0.2% of full scale

Other gases: ±1.5% of reading ±0.5% full scale - AC or DC power input available

- Optional hot tap packing gland and retractor

- Integrated and remote electronic configurations

- DigiSense™ robust sensor design

- Sensing elements supported at both ends

- Swivel probe +/-180° into four positions

- Gross Heating Value and Density Calculations of Gas Mix

- Measures gas flow rate in SCFM, MSCFD, KG/HR, and many more units

- Wide measurement range up to 1000:1 turndown;100:1 typical

- Negligible pressure drop

- Provides two galvanically isolated 4-20mA analog outputs, HART communication (optional), a pulse output, switch input, and Modbus RTU (RS485) (optional)

- Welded, 316 SS sensor construction

- Stainless or carbon steel inline flow bodies optional

- Low-end sensitivity for wastewater applications

- FM (U.S.) and FMc (CANADA) approved for Class I, Div 1; ATEX/IECEx approved for Zone 1

- NEMA 4X and CE Mark

Field Flexibility

- Microprocessor based, field-programmable electronics

- Standard on-board 2 line x 16 character,

- backlit display with configuration panel

- Free BioViewTM software available

- USB port to connect to a PC is standard

- BioCalTM calibration validation

- NIST traceable calibration

Sierra BioTrak 645i 745i - Datasheet

Sierra BioTrak 645i 745i - Manual

Sierra Wastewater BioTrak - Brochure

Sierra BioTrak 645i/745i BioView Software

Specifications

|

|

Call Us

Call Us